Home > Products > Die Cutting Machine > Feida High Performance Cardboard Flexo Printing and Punching Machine

Feida High Performance Cardboard Flexo Printing and Punching Machine

Technical Specification Model FD970x550Max cutting area 940mmx510mmCutting precision ±0.20mmPaper gram weight120-600g/cbmProduction capacity 90-180times/minAir pressure requirement 0.5MpaAir pressure consumption 0.25m³/minMax cutting pressure 150TWeight 6.5TMax roller diameter 16......

Send Inquiry

Product Description

Technical Specification

| Model | FD970x550 |

| Max cutting area | 940mmx510mm |

| Cutting precision | ±0.20mm |

| Paper gram weight | 120-600g/cbm |

| Production capacity | 90-180times/min |

| Air pressure requirement | 0.5Mpa |

| Air pressure consumption | 0.25m³/min |

| Max cutting pressure | 150T |

| Weight | 6.5T |

| Max roller diameter | 1600mm |

| Total power | 12KW |

| Dimension | 4500x2200x1800mm |

Introduction

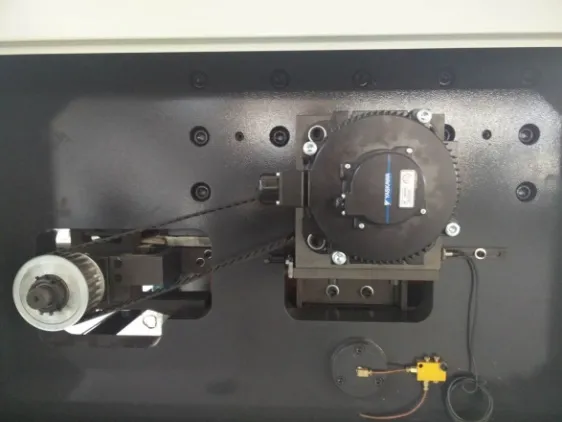

FD series automatic web die-cutting machine based on international advanced technology, has a high stability, high safety performance, high precision of the finished product, it's widely used in printing, packaging and paper products industries. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, automatic counting, manual pneumatic lock plate, photoelectric correcting deviation system, electromagnetic cluth, centralized oil lubrication, overload protection and distinctive gearing. So it guarantees smooth operations of returning paper and feeding paper, precise positioning and orderly withdrawing. All the key parts and controls of the machine are imported. Such installation can realize the machine in steady pressure, precise positioning, smooth moving, safety and reliability.

Main structure

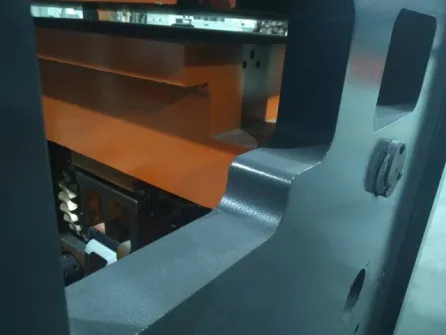

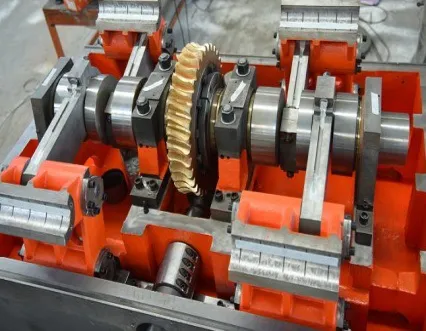

1.Worm Gear Structure: Perfect worm wheel and worm transmission system ensures the powerful and steady pressure and makes the cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure.

Main base frame, moving frame and top frame are all adopts high strength Ductile Cast Iron QT500-7, which has features of high tensile strength, anti-deformation and anti-fatigable.

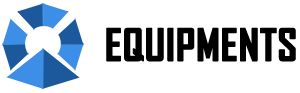

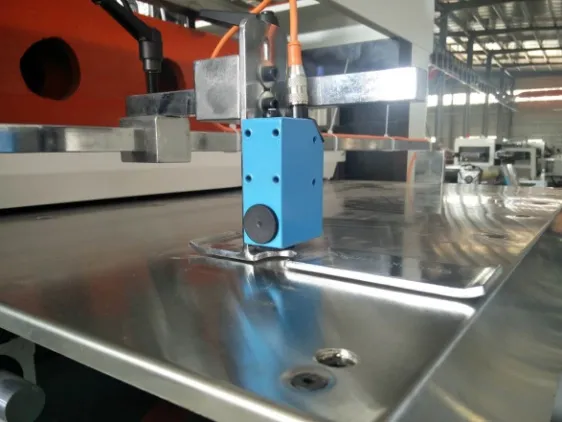

2. It can die-cut according to the printed words and figures or simply die-cut without them. The coordination between stepping motor and photoelectric eye which can identify colors assures the perfectly fit of the die-cutting position and figures. Simply set the feed length through the micro-computer controller to die-cut the products without words and figures.

3. Die cutting department adopts pneumatic lock version of the device to avoid come off from the machine.

Die cutting plate: 65Mn steel plate heating treatment, high hardness and flatness.

Die cutting knife plate and plate frame can be take out so that it can save plate-changing time.

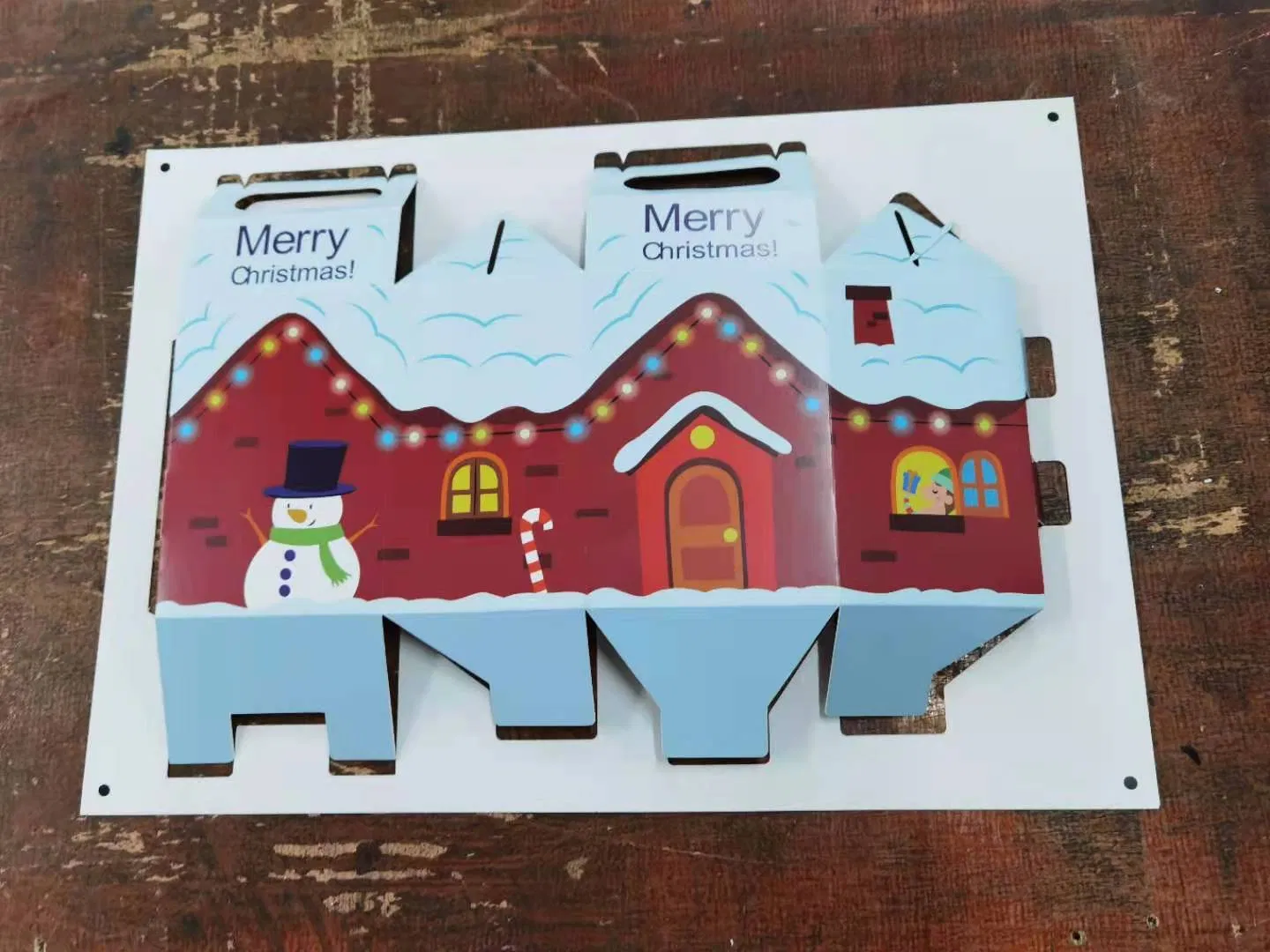

Printing machine

Characteristics:

1) Adopt the anilox roller to spread ink.

2) Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi.

3) Each printing unit adopt 360°for registration.

4) Each printing unit have one IR dryer

5) The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry.

6) The main motor is adopted the import stepless regulation of frequency conversion.

7) Unwinding, web guiding, printing, IR drying and punching can be finished in one process

Main Technical Variables:

| Web width | 860mm |

| Print width | 850mm |

| Unwind Diameter max | 1200mm |

| Press Speed max (Production speed depending on process, job etc.) | 80m/min |

| Gear Pitch | 1/8" (3.175mm) |

| Flexo Print Units (IR dryer): | 3 |

| Min.Max repeat Print Cylinder | 10" - 22.5" |

| Web Guiding: number | 1 |

| Overprint precision | ±0.15mm |

| Machine weight | 6000kg |

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.