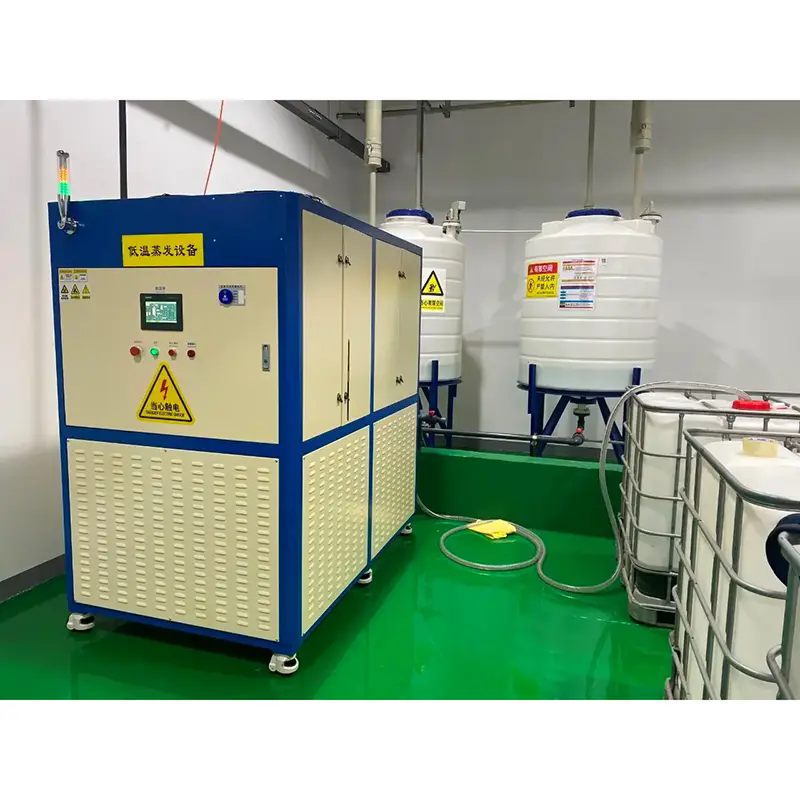

How Low-Temperature Evaporators Work

2025-08-25

Low-temperature evaporators have become indispensable in industries where precise temperature control, energy efficiency, and reliability are critical. From pharmaceuticals and food processing to chemical manufacturing and electronics, these systems enable businesses to achieve superior cooling performance while minimizing operational costs.

What Is a Low-Temperature Evaporator?

A low-temperature evaporator is a specialized cooling device designed to extract heat from a liquid or gas at extremely low temperatures, typically ranging from -40°C to -80°C or even lower, depending on the application. By reducing pressure inside the evaporator chamber, the system lowers the boiling point of the working fluid, enabling efficient evaporation at sub-zero conditions.

Core Applications

Low-temperature evaporators are widely used across industries where temperature-sensitive materials must be preserved or processed:

-

Pharmaceuticals & Biotechnology – For preserving vaccines, enzymes, and biologics.

-

Food & Beverage – Ideal for freeze-drying, deep freezing, and maintaining product integrity.

-

Chemical Processing – Supports controlled reactions and solvent recovery.

-

Semiconductor & Electronics – Maintains stability during delicate manufacturing stages.

-

Environmental Engineering – Used in cryogenic separation and cold recovery systems.

These applications demand stable performance, minimal energy loss, and precise temperature control, making low-temperature evaporators a key investment for modern production facilities.

How Low-Temperature Evaporators Work

At the heart of a low-temperature evaporator lies a thermodynamic principle: when liquid pressure drops, its boiling point decreases. The system leverages this principle through four main stages:

Low-Pressure Environment Creation

A vacuum pump or pressure control system reduces the pressure within the evaporator chamber, lowering the boiling point of the working fluid.

Heat Absorption

The liquid refrigerant inside the evaporator absorbs heat from the process material, causing it to evaporate rapidly at lower temperatures.

Phase Change

The absorbed heat converts the refrigerant into a low-temperature vapor, effectively extracting energy from the surrounding material.

Condensation and Recycling

The refrigerant vapor is routed to a condenser, where it transforms back into liquid form and recirculates through the system.

Key Technical Advantages

| Feature | Benefit |

|---|---|

| Ultra-low temperature range | Achieves cooling down to -80°C |

| Energy efficiency | Uses advanced thermal dynamics to reduce power consumption |

| Compact design | Saves space while maintaining industrial-scale capacity |

| High precision | Enables accurate control within ±0.1°C |

| Versatility | Adapts to multiple applications and refrigerants |

How to Choose the Right Low-Temperature Evaporator

Selecting the right low-temperature evaporator involves balancing performance requirements, operational costs, and application-specific needs. Below are key factors to consider:

Cooling Capacity

The evaporator’s cooling power, measured in kW or BTU/hr, must match your application requirements. For example:

-

Small-scale laboratories → 2–10 kW capacity

-

Industrial manufacturing → 50–500 kW capacity

Temperature Range

Different processes require different temperature levels:

-

Cryogenic food preservation → -50°C to -70°C

-

Semiconductor cooling → -60°C to -80°C

-

Pharmaceutical storage → -40°C to -60°C

Material Compatibility

Choose evaporators constructed with corrosion-resistant materials such as:

-

Stainless steel 316L for pharmaceutical-grade applications

-

Aluminum alloys for lightweight industrial designs

Automation & Control

Modern evaporators integrate digital monitoring systems with features like:

-

Real-time temperature feedback

-

Automatic defrost cycles

-

Predictive maintenance alerts

Energy Efficiency

Look for systems with:

-

Variable Frequency Drives (VFDs) to optimize compressor speed

-

Advanced insulation to reduce energy loss

-

Eco-friendly refrigerants to meet sustainability goals

FAQs: Low-Temperature Evaporator Common Questions

Q1: How does a low-temperature evaporator maintain consistent performance?

A: The system uses closed-loop temperature control combined with variable-speed compressors and intelligent sensors. These components continuously monitor pressure, temperature, and fluid levels, ensuring stable cooling performance even under fluctuating load conditions.

Q2: What are the maintenance requirements for low-temperature evaporators?

A: Regular maintenance includes:

-

Cleaning heat exchanger surfaces to maintain efficiency

-

Checking refrigerant levels and detecting leaks early

-

Inspecting sensors and valves to ensure accurate readings

-

Updating firmware for integrated control systems

With proper maintenance, high-quality low-temperature evaporators can operate reliably for 10–15 years.

Why Choose Our Low-Temperature Evaporators

At Fred Tech, we specialize in designing cutting-edge low-temperature evaporators engineered for superior reliability, energy savings, and operational excellence. Our products are built to meet international quality standards and feature:

-

Wide operating temperature range: -40°C to -80°C

-

High-efficiency refrigeration cycles for reduced energy costs

-

Customizable designs tailored to your industrial needs

-

Integrated smart control systems for real-time monitoring

Whether you operate in pharmaceuticals, food processing, chemical engineering, or electronics, our solutions deliver consistent performance and lower operational costs.

Take the Next Step

Ready to upgrade your cooling system and enhance operational efficiency? Explore our advanced low-temperature evaporators today.

Contact us to learn how we can provide a customized cooling solution tailored to your specific needs.