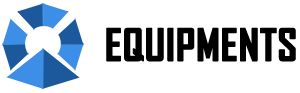

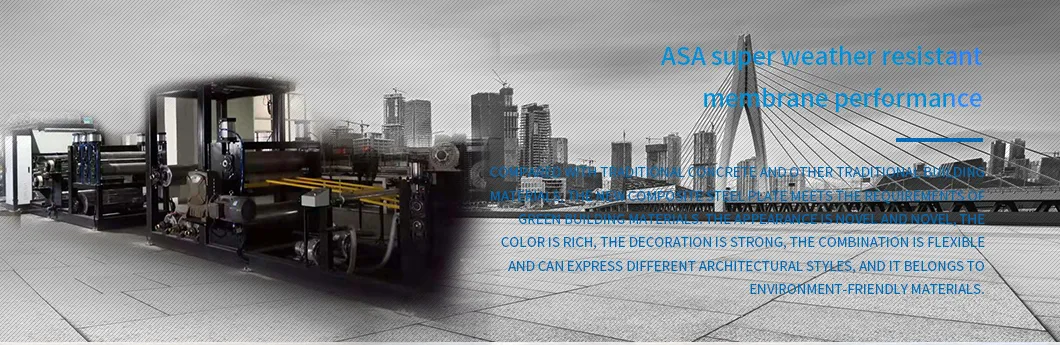

High Speed Solvent-Less Lamination Machine

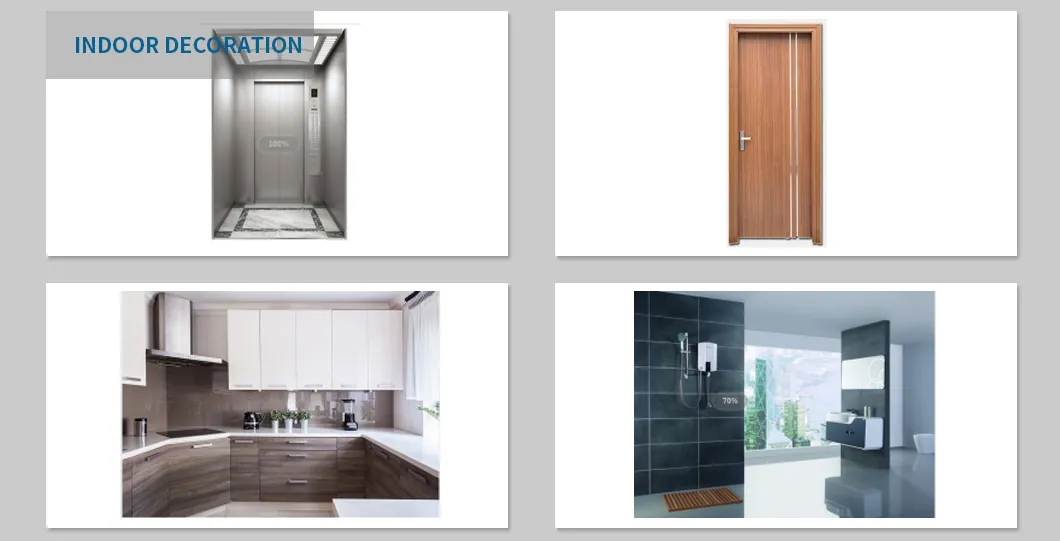

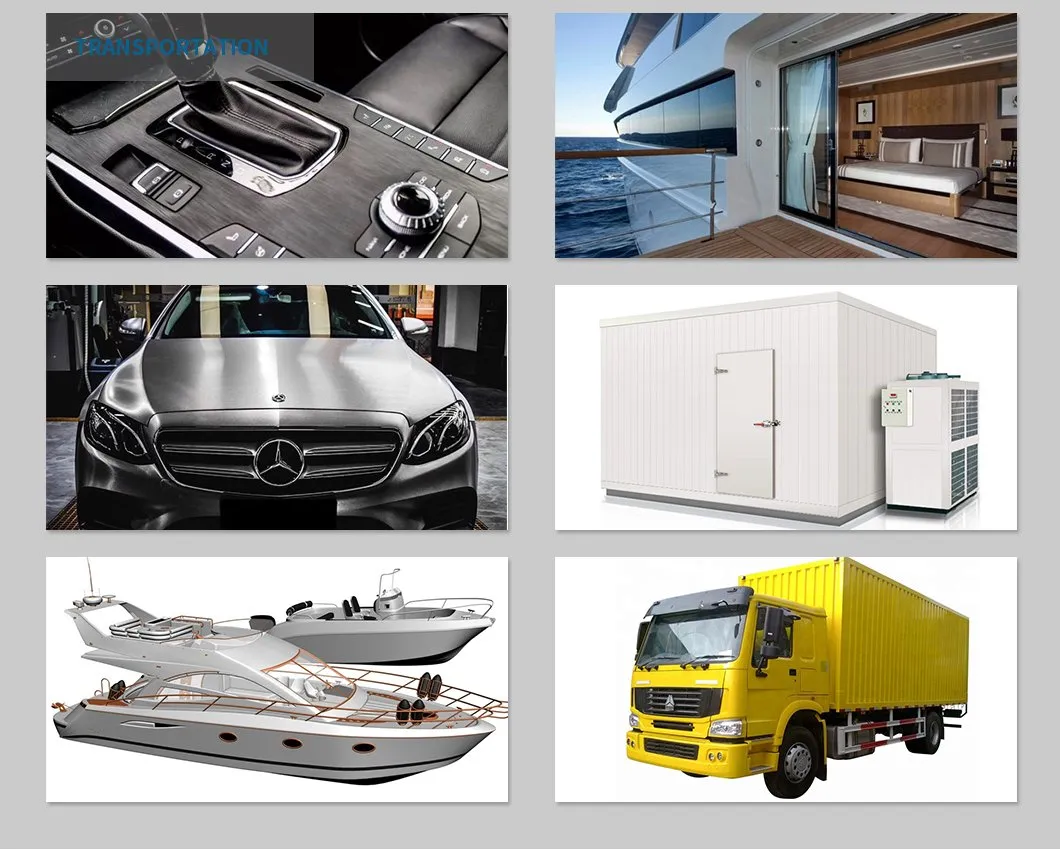

High speed Solvent-less Lamination machine Production Description: This machine is suitable for composite of color steel coil with PET color aluminum film, pure aluminum film, PVDF, ASA, PVC film (plastic steel roofing tile), stainless steel with color film (home appliances, door plate). Humanized d......

Send Inquiry

Product Description

High speed Solvent-less Lamination machine

Production Description:

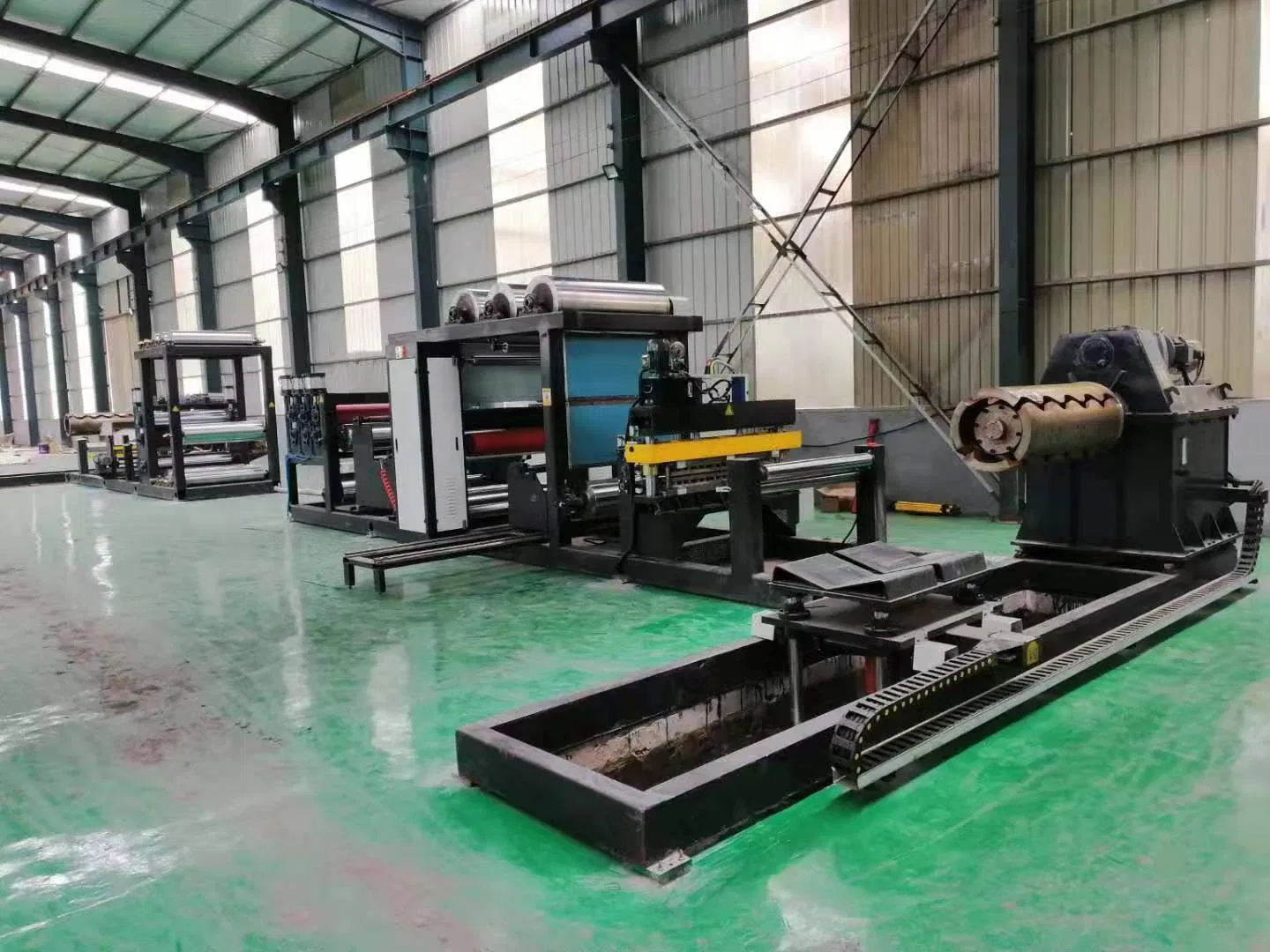

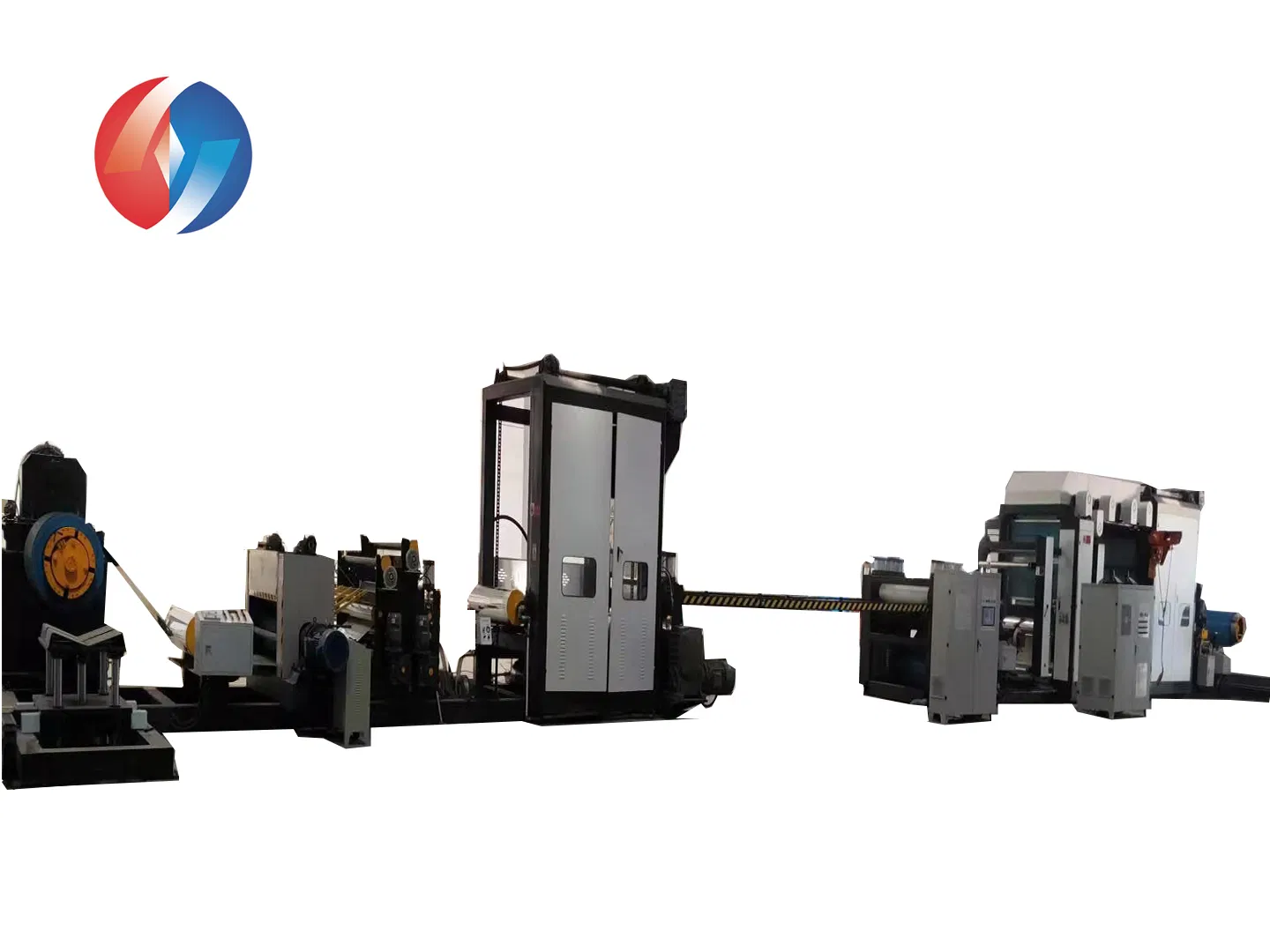

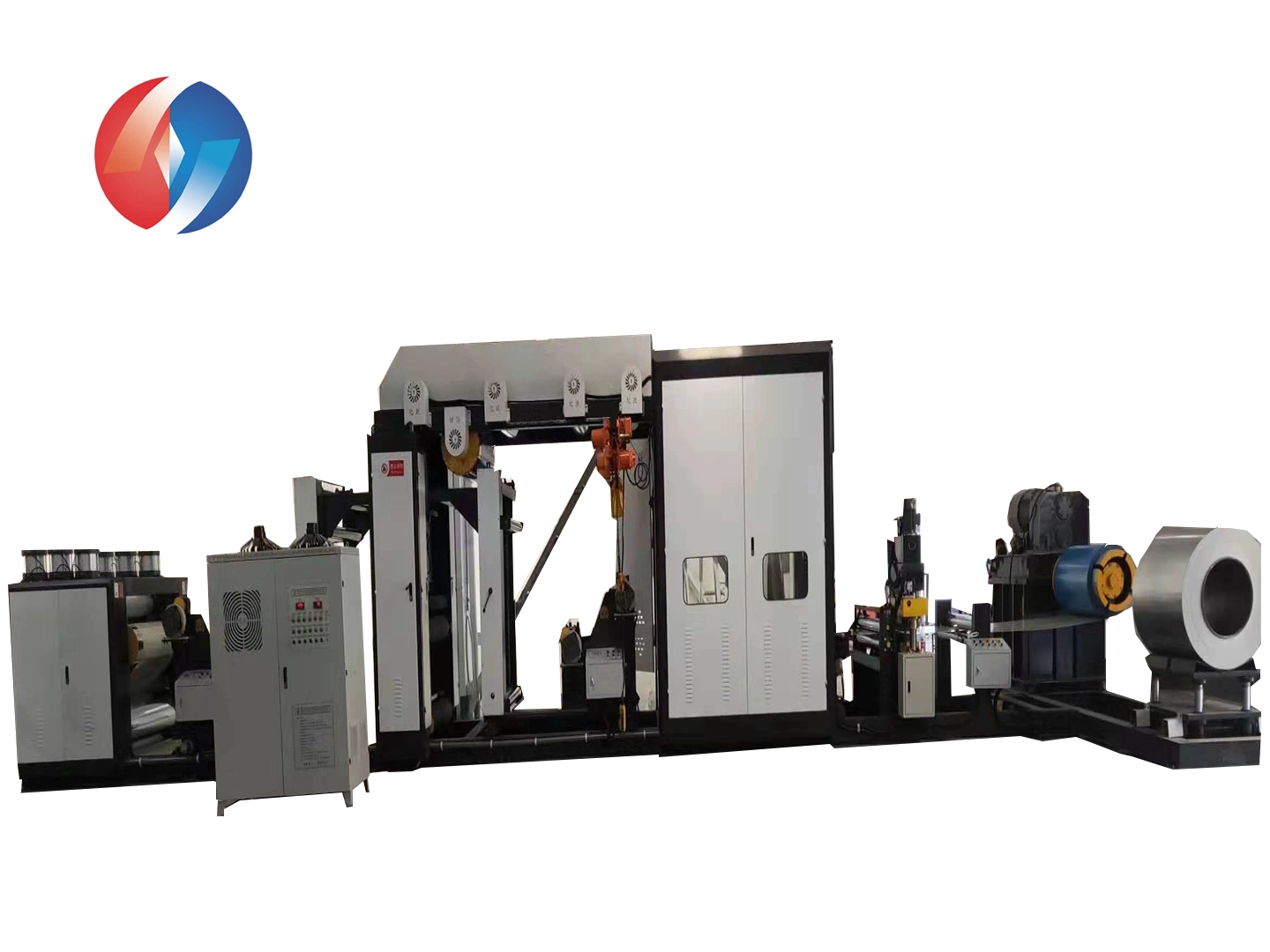

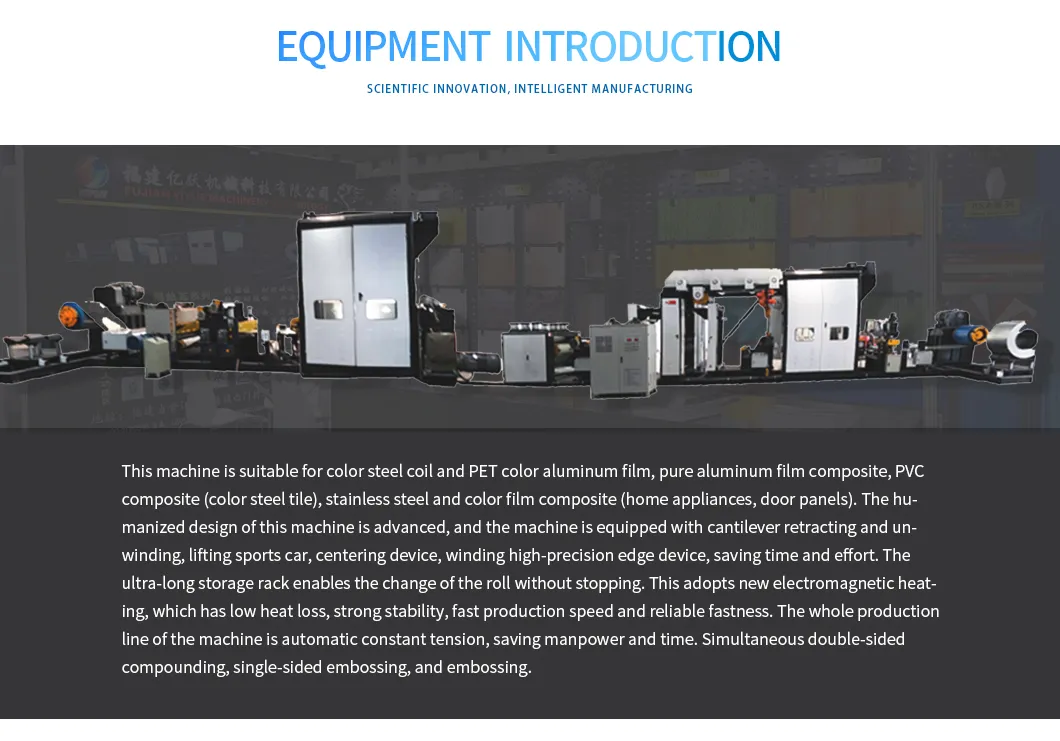

This machine is suitable for composite of color steel coil with PET color aluminum film, pure aluminum film, PVDF, ASA, PVC film (plastic steel roofing tile), stainless steel with color film (home appliances, door plate). Humanized design, advanced technology, this machine with cantilever winding, lifting sports car, alignment device, winding high precision alignment device, save both time and labour.

Super long material storage rack, realize rewinding without stopping. High-power seam welding machine, shear machine, alkali washing tank, clean water tank. It caused rapid aging of products because of large heat loss and poor thermal stability of oven. This machine adopts no oven heating which low heat loss, strong stability, fast production speed, reliable fastness. The whole production line of this machine is automatic constant tension, saving manpower and time. Double-side film-lamination at the same time , single - sided embossing, concave embossing are all available.

Main Technical:

This machine is suitable for composite of color steel coil with PET color aluminum film, pure aluminum film, PVDF, ASA, PVC film (plastic steel roofing tile), stainless steel with color film (home appliances, door plate). Humanized design, advanced technology, this machine with cantilever winding, lifting sports car, alignment device, winding high precision alignment device, save both time and labour.

Super long material storage rack, realize rewinding without stopping. High-power seam welding machine, shear machine, alkali washing tank, clean water tank. It caused rapid aging of products because of large heat loss and poor thermal stability of oven. This machine adopts no oven heating which low heat loss, strong stability, fast production speed, reliable fastness. The whole production line of this machine is automatic constant tension, saving manpower and time. Double-side film-lamination at the same time , single - sided embossing, concave embossing are all available.

Main Technical:

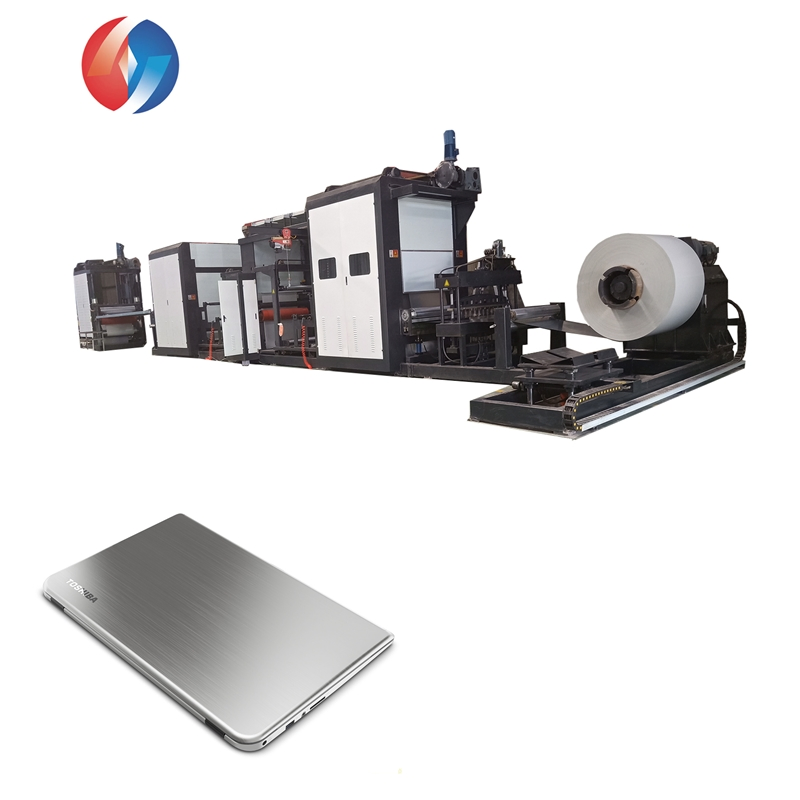

| Model | KY-1901 |

| Basic Material Thickness | 0.18~0.5mm |

| Specification | L18m * W6.3m * H3.5m |

| Input Power | 230KW |

| Vehicle Speed | 0-60 m/min |

| Equipment table size | ≤1300mm(Coil Width:500~1150mm) |

| Vertical Laminating | |

| Hot Melt Laminating Machine | |

Detailed description |

| 1) Decoiling machine:hydraulic automatic edge matching, equipped with hydraulic trolley, decoiling machine motor 11KW level6 |

| 2) Plug-in splicing machine:hydraulic control, thickness of splicing plate is below 0.5mm |

| 3) The diameter of the front auxiliary heating roller is 350mm.Electric heating tube heating, automatic temperature control |

| 4) Super audio heating, heating power can follow the speed of the machine |

| 5) Super audio heating, heating power can follow the speed of the machine |

| 6) Super audio heating, heating power can follow the speed of the machine |

| 7) 500mm diameter heating roller with automatic temperature control |

| 8) 500mm diameter heating roller with automatic temperature control |

| 9) 500mm diameter heating roller with automatic temperature control |

10)Under film release process, automatic constant tension, with correction function 11)Super audio heating, infrared probe, automatic temperature control |

| 12)The diameter of the compound heating roller is 350mm, the electric heating tube assists the heating, and the temperature is automatically controlled. 13)Four kinds of embossing roller combination embossing (diamond, dot, orange peel pattern, cylinder diameter 200m), electric heating tube auxiliary heating, automatic temperature control 14)Overlay film release process, with dual station film release, automatic constant tension, with correction function 15)Cooling station, equipped with 6 sets of 350mm cold water rollers, good cooling effect 16)Main engine traction, main engine rubber roller diameter is 400mm, cylinder diameter is 200mm, gear box is 200 type, motor is level 4 11KW 17)Trimming device, automatically track the side and automatically suck the side material 18)Shearing machine, cutter motor is 2.2KW, easy to cut 19)Recoiling machine, hydraulic automatic edge matching, equipped with hydraulic trolley, unwinding motor is level 6 22KW |

Product process

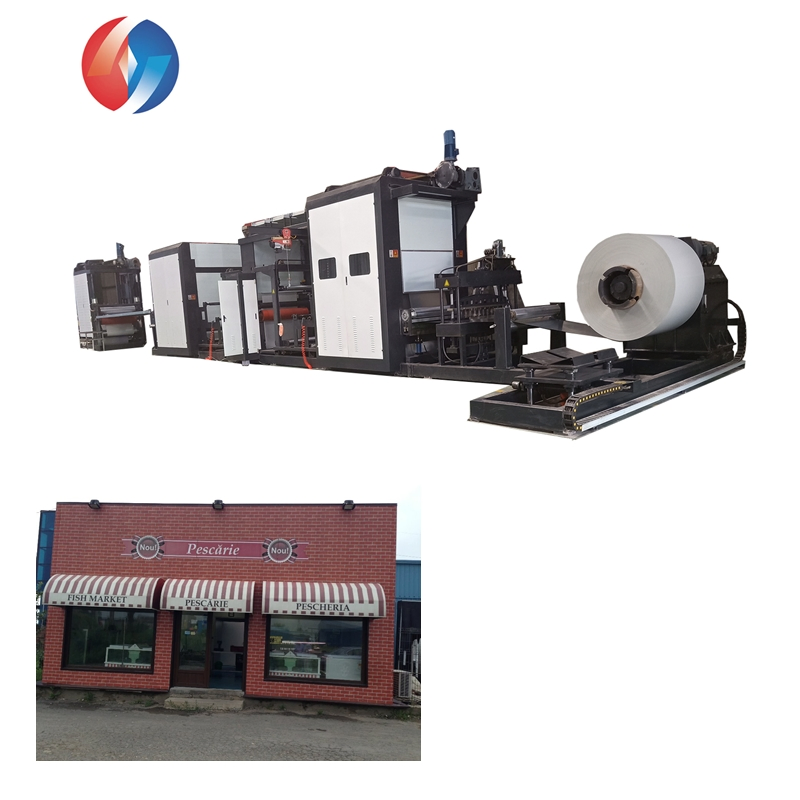

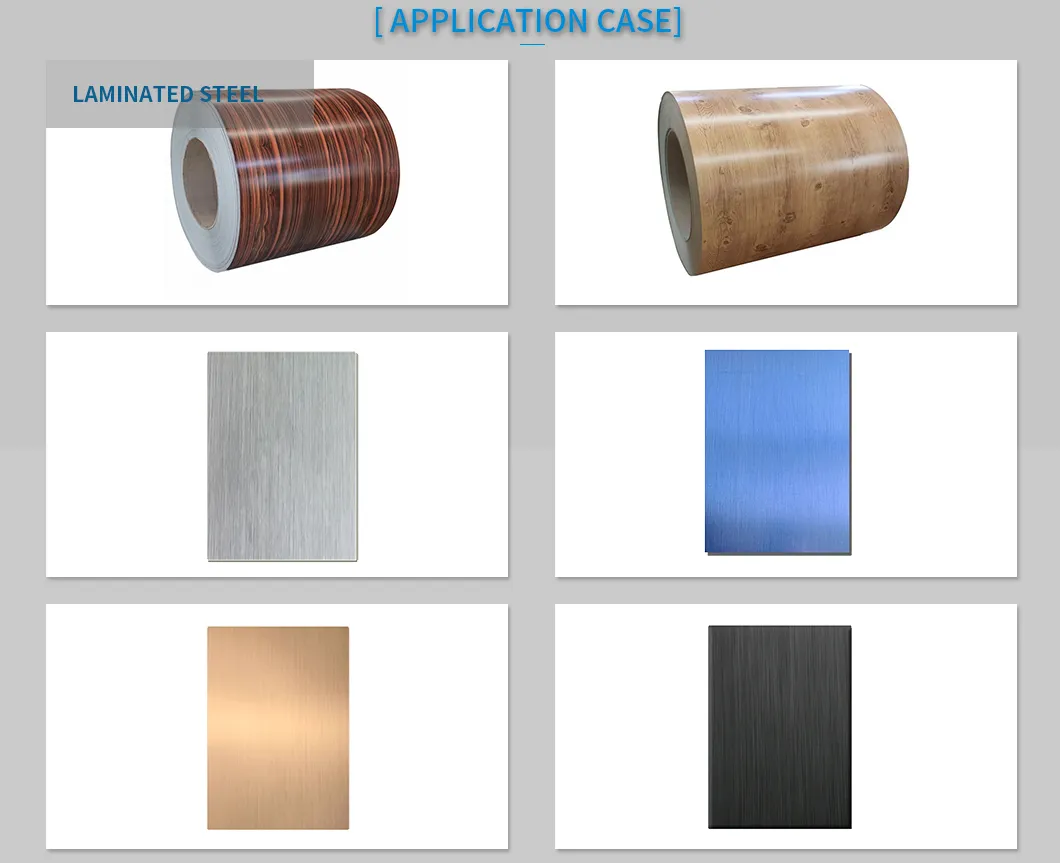

Adopt plastic film(PET,PVC,PVDF,ASA) combined with metal plate through hot melting, which has solved the corrosivity of metal plate and metal container, both has the decorating, barrier of plastic film and the malleability, figurability of metal sheet.

Metal plate: galvanized sheet, Stainless Steel sheet,Cold Rolled Sheet,Aluminum Sheet.

Plastic film:PET, PVC,PVCF,ASA etc.

Film color:RAL Color/Pantone Color;Wood Grain,Marble Grain,Brick Grain,Stone Grain,Flower Pattern,Brushed,Embossed

Advantages of Laminated steel:

1,Increase security:The film is directly applied to the metal surface and no longer use various solvents to solve the problems of bisphenol A.

2,Excellent processing performance:Processing resistance, abrasion resistance, not easily be damaged during processing.

3,High chemical resistance:Ageing resistant , corrosion resistant, can adapt to the harsh environment without shedding and rusting.

4,Green,energy-saving and pro-environment:Simplify the drying and fixing process,greatly reduce the energy consumption and CO2 emissions

5,Saving costs during canning process:Remove the inner coating and base coating, simplify the canning process, save costs.

Our Service:

Pre-Sales Service

* Inquiry and consulting support.* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.* Engineers available to service machinery overseas.

Our laminated product:

Surface is shinning, smooth and good touching, well decorated

anti-wearing, anti rust strong chemical stability, anti-corrosion

well formed, can be deep formed,less sticky to ink

so comparing to the traditional printing technology, this makes the container more stable and better decorated.

We can develop and customize the laminating machine according to your package design and requirements,high speed and quality steady.If you have any requirements or need more details,please feel free to contact with us.

For more information,please contact below.

Joyce

Overseas Sales

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.